Lowbed Semi Trailer

-

60 Ton Lowbed Trailer

-

Tri Axle Low Bed Truck Trailer

-

3 Line 6 Axle Low Loader Trailer

-

80 Ton Lowbed for Sale

-

3 Axle Low Bed Trailer Price

-

5 Axle Semi Low Bed Trailer

-

100 Ton 4 Axle Lowboy Trailer

-

Triple 60 Ton Low Bed Vehicle

-

50 Tonne Lowboy Equipment Trailers

-

2 Axle Low Bed Semi Trailer

-

100T Lowbed Trailer Sale

-

4 Axle Low Loader

Table of Contents

1. What is a lowbed semi trailer?

The lowbed semi trailer is mainly used to transport special vehicles, mining machinery, agricultural machinery, construction machinery, large tank body equipment and other heavy plates. The lower the center of gravity of this series of trailers, the better the stability and safety, and the stronger the ability to transport super high and heavy cargos.

The front section of our most common lowbed semi trailer is a gooseneck type structure (the traction pin under the gooseneck is connected to the saddle on the tractor), the middle section is a cargo loading platform, and the rear section is a ladder for cargo loading and unloading.

According to the number of axles and the size of the tires, the loading capacity of the lowbed semi trailer is different. The more axles, the greater the loading capacity, usually 20-150 tons. If you have special needs, we can also design or customize for you.

2. Application scenarios of lowbed semi trailer

YUHANG lowbed semi trailers are widely used, efficient and fast, and are mainly used for medium and long-distance transportation of heavy machinery and equipment (such as: excavators, bulldozers, loaders, paving machines, cranes) and other goods.

Our 3 axle/4 axle/5 axle/6 axle lowbed trailers are exported to more than 50 sets countries including Zambia, Ghana, Malawi, Mozambique, Liberia, Madagascar, Mauritius, Vietnam, Philippines, Indonesia, Uruguay, Chile, Guyana, etc. It has achieved unanimous praise and love from customers, and has brought good profit value to their business.

3. Different types of lowbed trailers for sale

YUHANG factory is a professional truck semi trailer manufacturer, and has provided a large number of lowbed trailers for sale to many countries. We have more advantages in sales price and quality control. Our lowbed trailers have many types, such as:

30-80 tons lowbed trailer

With a loading capacity of 30-80 tons, it is the most widely used common type of lowbed trailer at present. Customers often choose 3 axle or 4 axle low loader, which can be used to transport excavators, loaders, harvesters, and road rollers. The main platform has a low center of gravity, which improves stability during transport.

80-120 tons low loader trailer

The cargo capacity of the 80-120 ton low loader trailer has been greatly improved, and it is mainly used for transporting heavy machinery and equipment. Our engineers will thicken the main beam of the trailer, assemble heavy machinery suspension and thicken and widen the leaf spring to ensure that it can better adapt to the work.

Gooseneck detachable lowbed trailer

The gooseneck of the detachable lowbed trailer is generally equipped with 4 hydraulic devices, one group is used for the lifting of the gooseneck, and the other group is used for the forward and backward movement of the gooseneck for easy disassembly, so as to ensure that the goods can be loaded and unloaded quickly from the front. It is safer to load heavy objects in this way.

Multiple axles lowbed trailer

The multiple axles lowbed trailer has at least 5 axles or more, some countries have strict restrictions on single-axle load, if you want to transport heavier cargo, you can only increase the number of axles to meet the demand. This type of trailer is mostly used to transport generators, bridge structures, cylinders, wind power towers, chemical tanks, etc.

4. Common structures of lowbed trailers

We have low deck semi trailers for sale in different structures and styles, such as: 3 axle low deck trailers, 4 axle low loaders. The three most common lowbed trailer structures are described below:

Flatbed Style: lowbed trailers in this construction style are more common and a customer favorite. It can transport all kinds of light and heavy mechanical equipment or other goods. The middle part is the loading platform, and the goods can be quickly loaded and unloaded through the mechanical or hydraulic ladder at the rear.

Concave Beam Style: concave beam low-slab semi trailers usually use beam-through axles and reverse suspension to reduce the height of the bearing surface. It has the characteristics of low center of gravity, high stability, and convenient loading. It can increase the number of axles and improve the load level.

Exposed Tire Style: effectively reduces the height of the cargo platform from the ground, and increases the safety performance of the trailer for carrying heavy or large-diameter cargos.

5. YUHANG lowbed trailer specifications & payload

The load capacity of a lowbed trailer is mainly achieved by the frame, that is, the most important factor affecting the load capacity of a low bed trailer is the trailer frame. Theoretically, the stronger and more durable the trailer frame, the higher the quality and strength, and the better the load-bearing capacity. In addition, the number and specification of axles, the type and design of tires, the type of suspension, and the thickness of leaf springs also have a certain impact on the load of lowbed trailers.

YUHANG has more than 20 years of lowbed trailer production and export experience, we can provide you with low bed trailers with different load requirements. Such as: 2 axle low bed semi trailer, 3 axle lowbed semi trailer, 4 axle lowboy trailer, 30 ton low loader trailer for sale, 50 ton low bed trailer for sale, 80 ton lowbed truck trailer, 100 ton lowbed semi trailer for sale, 120 tons lowbed trailers for sale, 150 tons low bed trailer, 200 tons lowbed trailer for sale.

We also provide exclusive design and customization services to ensure that lowbed trailers can meet the requirements of more customers.

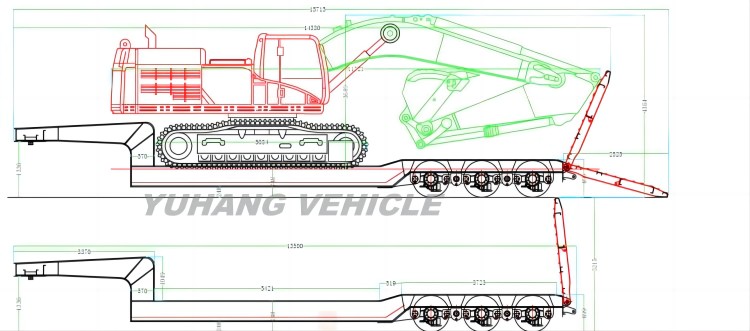

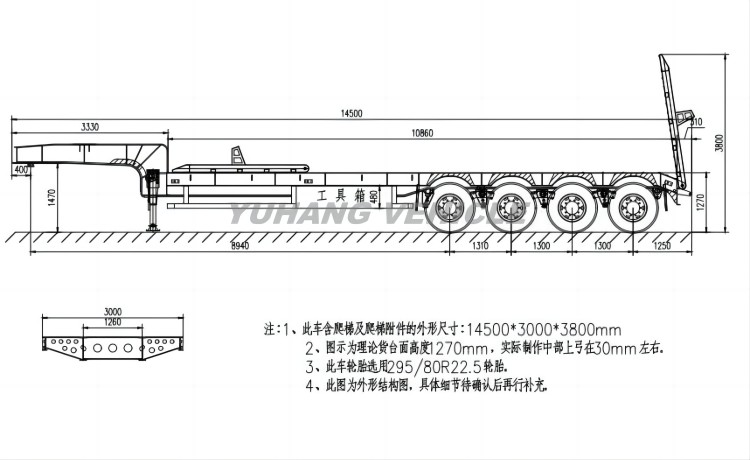

6. Lowbed trailer drawings

3 line 6 axle low loader trailer technical drawing

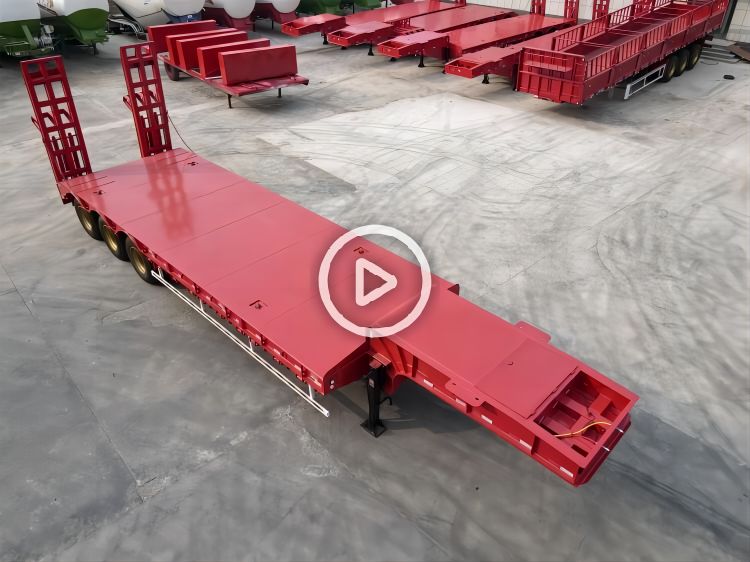

7. Lowbed trailers picture & video

8. Low loader trailers technical specification

Model: YUHANG Low Loader Trailers For Sale

Loading Capacity: 30-90 tons or customized

Weight: about 8-14 ton

Overall Dimension: 13000mm*3000mm*3400mm(the specific size is subject to actual needs)

Material: Q345B high strength steel plate

Main Beam: height 500mm-550mm, upper plate 14mm-25mm, middle plate 8mm-15mm, lower plate 16mm-25mm

Side Beam: 16mm or 18mm channel steel (Q235 steel)

Axle: 3 axles, 4 axles, 5 axles and more

Suspension: heavy duty mechanical suspension or air suspension

Spring Leaf: 90(w)mmx13(thickness)mmx10 layers

Tires: 8.25R20/10.00R20/11.00R20/12.00R20/12.00R22.5

Langing Gear: JOST brand

King Pin: 90#

Rear Ramp: spring ladder or hydraulic ladder

Electical System: 24V, LED lights

Brake Valve: WABCO valve

Accessories: one tool box, spare tire carrier

ABS: optional

9. Lowbed trailers test

YUHANG VEHICLE’s pursuit of high quality has always been at the forefront of the industry. All lowbed trailers need to be tested for loading capacity under the guidance of specialized technicians after production is completed.

10. Lowbed trailer transportation plan

Our lowbed trailers are packaged and transported by professional personnel who have undergone strict training. We will spray a layer of wax on the lowbed trailer and cover it with a moisture-proof cloth to prevent corrosion from seawater and rainwater during transportation.

We will choose a professional freight company to transport the lowbed semi trailer by bulk carrier or Ro-Ro ship or containers, providing you with the best cost-effective transportation solution, saving cost and timeliness.

11. YUHANG lowbed trailer factory image

The fundamental reason why YUHANG lowbed trailers sell well is to strictly control the quality and pay close attention to product quality from the source. Undoubtedly, this is the right step and a powerful guarantee for us to go to the world and be continuously recognized by customers. We welcome you to visit the factory and exchange experience, the following are the feedback photos of the 4 axle lowbed trailer during the production process.

12. Low loader trailers manufacturing process

After you sign low loader trailers purchase contract with YUHANG VEHICLE, our technicians will make drawings according to the specifications and parameters stipulated in the contract. After the drawings are confirmed, we will arrange production immediately.

Step 1: Cutting stage of steel plate material

First, complete the plasma CNC cutting work of the main beam, side beam, web and other components according to the drawing requirements.

Step 2: Fix the main beam by submerged arc welding

The next step is to assemble the cut web and the upper and lower flanges of the main beam, and then use submerged arc welding to weld them firmly.

Step 3: Main beam opening and throughing

Then cut U-shaped hole on the web of the main beam so that the longitudinal beam can pass through smoothly, and then fix the welded I-beam in parallel. At this time, it is necessary to calibrate the horizontal error of the two I-beams, otherwise the lowbed trailer will be skewed.

Step 4: Connect the side beams and weld the king pin

At this time, the main beam has been formed, and it is only necessary to weld the side beams to form a frame structure, and weld the traction pin to the position specified in the contract.

Step 5: Weld the frame and suspension system

The suspension welding must strictly control the size and keep it vertical, otherwise it will cause tire wear on the 50 tonne lowboy equipment trailers for sale.

Step 6: Fix the front gooseneck

We weld the front gooseneck of the lowbed trailer, and then weld the reinforced steel plate to improve the overall running strength of the trailer.

Step 7: Lay the base plate and weld

The bottom plate is laid, pressed and integrally welded to the frame.

Step 8: Sand cleaning and painting

Painting is a very important link. Before painting, we will scrub and clean the 3 axle lowbed trailer to eliminate welding slag and rust, and improve paint adhesion and aesthetics.

13. Why choose YUHANG low loader trailer?

In reality, our lowbed trailers will impress you with a clear price and quality advantage over other competitors.

1. For the same type of tri axle low deck trailers, our main beam adopts high-strength pressure-resistant and wear-resistant steel plates to ensure a long service life and avoid unnecessary maintenance costs.

2. The whole vehicle adopts advanced computer-aided software to optimize the design structure, track and analyze the running data of the frame, and ensure the maximum load of the trailer when it is working.

3. Adopt branded axles and heavy mechanical suspension system to ensure its anti-twisting, anti-vibration and anti-turbulence capabilities, and adapt to more rough and bad road conditions.

4. YUHANG adopts 4mm-6mm thick patterned non-slip floor to ensure safer and more stable cargo transportation.

5. We usually design 250mm or 300mm wide extension arms on both sides of the 60-ton low loader trailer to meet the loading of special cargo. We will add on your lowbed semi trailer if you need it.

6. The lengthened and widened design structure of the ladder at the rear end minimizes the angle between it and the ground, making it easy for large machinery and equipment to climb onto the low bed trailer.

7. During the use of the low bed trailer, we will have specialized technicians to guide you in using it and answer any questions you encounter at any time to help you carry out your business smoothly.

14. How to care and maintain our low bed trailers?

When using low bed semi trailer, attention should be paid to strengthening maintenance and maintenance to increase the flexibility of the vehicle. Here are a few maintenance tips:

1. Tires are the main part of the 4 axle 80 tons low bed trailer that touches the ground. If the road conditions are not good, the speed of tire damage will be aggravated, so you should choose to drive on a flat road as much as possible to improve transportation efficiency.

2. Always pay attention to prevent the vehicle from being overweight. If the load exceeds the regulations, it will accelerate the damage of the vehicle, or even cause a tire burst, which will greatly reduce the service life of the low bed trailer.

3. It is recommended to check the air pressure in the tire frequently to better ensure our transportation needs.

4. During the operation of the vehicle, the chassis is close to the road and is easy to corrode, so we must pay attention to the cleaning and rust prevention of the chassis.

5. During the rainy season, check the electrical system of the vehicle frequently to prevent leakage.

6. The body is waxed and glazed to enhance the corrosion resistance of the trailer and keep the paint surface beautiful.

You are welcome to contact us anytime to get the latest exclusive quotation.